The "smart" concept

In an era of rapidly advancing technology, we live ever more alongside smart devices, designed to make our lives more efficient, more comfortable but at the same time bringing more competitiveness in the marketplace. From our smart phones, to our smart TV's and soon to have smart driverless vehicles, where all devices and appliances around us will be connected to world wide web under the buzz phrase, "internet of things", it is only a matter of time when businesses will have to adopt this same concept in their DC under the term smart storage.

Indeed for many decades and under a stagnant slow changing market, storage systems used to be boring static structures that only carried dead weight. Nowadays however, with the enormous transformation in our lives that technology has brought to us, the needs of the distribution center require more than ever before to be more nimble, agile and error free. As a result the legacy storage system of static structures has given way to the smart storage concept. The concept of "goods to man".

Goods to man is by no means a new principle but now more than ever is the time to consider the adoption of such smart systems as the market is about to transform further and at an ever more accelerating pace than it has done up to present. Businesses that fail to transform with market change will find themselves lagging behind at best and face much more ruthless competition. Today's end customer is highly informed and expects a high level of service and fast turnaround on goods ordered. Corporations that only start to adopt the latest technology, will be able to maintain this level of service needed to keep a high level of customer satisfaction and retention.

Dynamic systems

While fully automated warehouses have been around for many years now and are suitable only for very high levels of throughput, small to medium businesses can benefit from the so called semi-automation; this means that some form of manual handling step will be needed between the end to end logistics process i.e. from goods ordered to goods dispatched and from goods in to goods stored.

One such smart system for small items picking, is the SSI LogiMat.

What is a LogiMat?

The LogiMat's concept simple; it is built as a tall tower, thereby utilizing the room's height and as a result requiring much less floor area in terms of storage (see images below showing conventional multi-tier shelving). Secondly and most importantly however, it operates the goods to man principle. This means that unlike conventional shelving where pickers have to walk inside the system and very often go up multiple staircases to higher levels, the LogiMat brings the item to the picker. The benefits are therefore plenty to go around...

Advantages

Here are some benefits to consider against traditional shelving systems:

Reduction of floor area needed by up to 90% (provided sufficient height is available). Floor area comes at a premium whereas your room's height is free. Why not utilise it to your full capacity and have area available for future expansion?

Travel times are reduced by 70%. Think of it... pickers walking in and out of shelving, up and down tiers, picking and filling carts and processing orders. Why not eliminate all that time waste by having a machine bringing parts to you? Pickers can be reduced to 1 operator per machine; a lot of operational savings there.

Elimination of errors in the picking process: Humans are prone to error especially in times of peak activities and working under pressure. This again adds un-needed time to the pick process with regards correcting errors. A machine will not make picking errors.

Plenty of options for ergonomics: aside from the basic machine routine of storage and retrieval of goods there are also a variety of add -ons that ensure the highest levels of ergonomics for the user. This of course in turn results in an unquestionable increase in the performance of the operator.

How it operates

Simply put, the operator logs in to the machine by use of the touch screen panel just above the access opening and inputs the part number of the desired item, or inserts a USB stick with the order in XML format (an open format for transporting data between systems). After acknowledging the command the system's tray transporter will travel to the desired tray location in the tower and deliver it straight to the operator for picking. The machine can also be equipped with a bar code scanner and linked to the software for easier order processing.

During the replenishment process this is of course done in reverse; via the touch screen the user will confirm the items added to the bin prior to the system carrying the goods to the storage place.

Each tray can hold numerous SKU's via an assortment of plastic bins and the system administrator can map each SKU in the tray interactively via the touch screen panel.

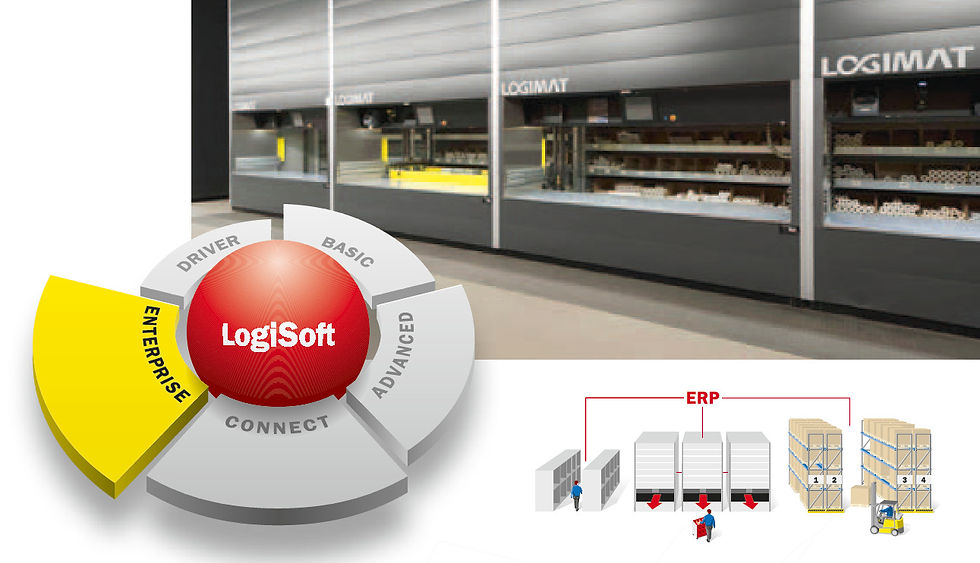

The above described is the machine at its most basic. The LogiMat ships with a variety of softwares (LogiSoft) according to customer needs, allowing it to carry out more complex functionality.

The advanced software packages for example allows for integration into popular business software systems such as SAP, that can then drive the order process itself via the LogiMat. Furthermore, the advanced LogiSoft options can enable the operation of multiple LogiMats, access to a multitude of ergonomic and optimisation features and also go a step further by handling the entire logistics process between it and other storage systems in the DC such as pallet racks and shelving systems.

As an advanced option, the customer can also have the intelligent height optimisation (IHO) feature, whereby the system allocates storage in the tower dynamically according to the height of goods in the tray, to allow the best use of available storage within the LogiMat.

Optionals to the LogiMat

In addition to the above, the latest generation of LogiMat has a host of new features that make it a true leader in the market of small item logistics. The most important ones are summarised below but for a comprehensive list and explanation you can contact your local SSI Schaefer office:

LogiDriver: PLC interface for connection to customer systems

LogiDual: Queued tray movements for increased performance

LogiGate: Automatic lifting gate for protection of operator, stored goods and reduced noise

LogiPointer: Laser pointer to specific location of selected item in tray

LogiPower (Fast drive): Increased travel speed for faster access times

LogiPriority: Prioritization of access times by sorting into ABC categories

LogiPull: Manual tray extension

LogiSpeed: Individual speed adjustment for each tray for gentle goods transport

LogiStainless: Long lasting corrosion and scratch resistant covering of the operating opening with chrome plated steel.

LogiTilt: User defined tilt of tray for optimal ergonomic picking of goods

LogiWeight: Weight check of trays for overload prevention

LogiWork: User defined height adjustable tray for optimal ergonomics

Conclusion

Operating a small parts storage facility can be complicated and also require numerous shelf levels due to the need of having a separate labelled location per SKU. This means many pickers executing many trips to process the daily orders. So owning a LogiMat would be an invaluable investment to any such business. The reduction in operational costs as well as the elimination of errors makes this product a no brainer.

Comments